Engraft® (Functional Polymer)

Grafted Polymers are co polymers which has reactive functional group grafted over linear backbone of polymeric chain.

Grafted Polymer works as Impact Modifier, Coupling Agent and Compatibilizer in various polymers like PP, PE, PC, PBT, Nylon, ABS etc.

It helps in increasing mechanical properties like Izod Impact, Tensile Strength, Elongation etc. It helps in coupling in glass reinforced compound and mineral filled compounds. Also, it helps in blending of two different polymers like PC-ABS, PC-PBT, Nylon-PP, HD-LD etc.

| Grade | Base Polymer | MFI (190C 2.16KG) (g/10 min) |

Density (g/cc) | Graft Ratio | Applications |

|---|---|---|---|---|---|

| PP-25 | PP Homo | 80-110 | 0.92 | High | Coupling Agent for filled PP, PP WPC and PP/PA alloy. |

| PP-20 | PP Homo | 40-70 | 0.92 | Medium | Coupling Agent for filled PP, PP WPC and PP/PA alloy. |

| MD-72 | PE | 1-3 | 0.95 | High | Coupling agent for PE based WPC. |

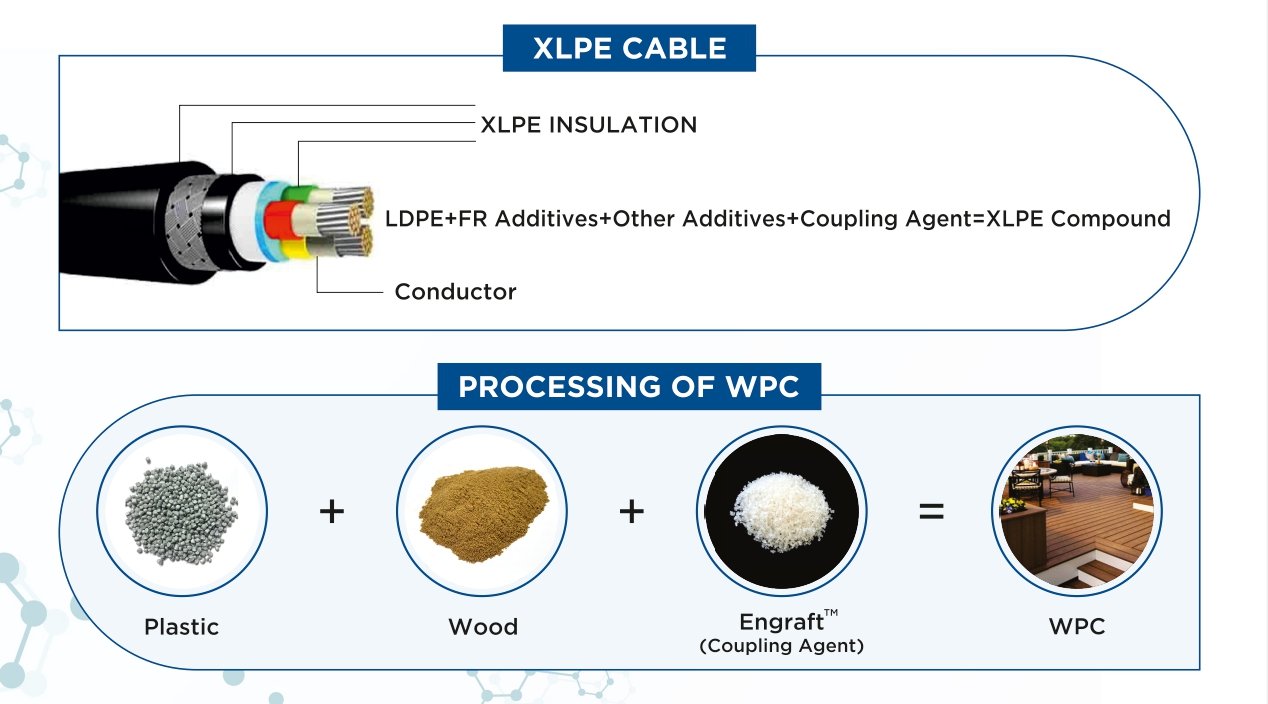

| ML-560 | PE | 0.5-1.0 | 0.92 | High | Coupling Agent for XLPE cable, LDPE, PA. |

| MT-40 | VLDPE | 0.4-0.6 | 0.87 | High | Coupling Agent & Impact modifier for PA, PP. | MS-30 | SEBS | 0.1-0.5 | 0.91 | High | Used for super toughning of PA and PPA |

| ST-80 | Styrene | 5-6 | 1.17 | Very High | Coupling Agent ABS and its Alloy. |

| MB-710 | PLA | 8-12 | 1.25 | High | Coupling Agent and Compatibilizer or PLA |

| MB-720 | PBAT | 4-5 | 1.25 | High | Coupling Agent and Compatibilizer or PBAT |

| MB-740 | PBS | 13-15 | 1.2 | High | Coupling Agent and Compatibilizer or PBS |

Note: TDS & SDS available on request.

| Grade | Base Polymer | MFI(190C 2.16KG) (g/10 min) |

Density (g/cc) | Graft Ratio | Applications |

|---|---|---|---|---|---|

| GT-460 | VLDPE | 3-8 | 0.88 | High | Coupling Agent and Impact modifier for PBT, PET, PC. |

| GE-45 | PE | 20-25 | 0.9 | High | Coupling Agent for PBT, PC, PET. |

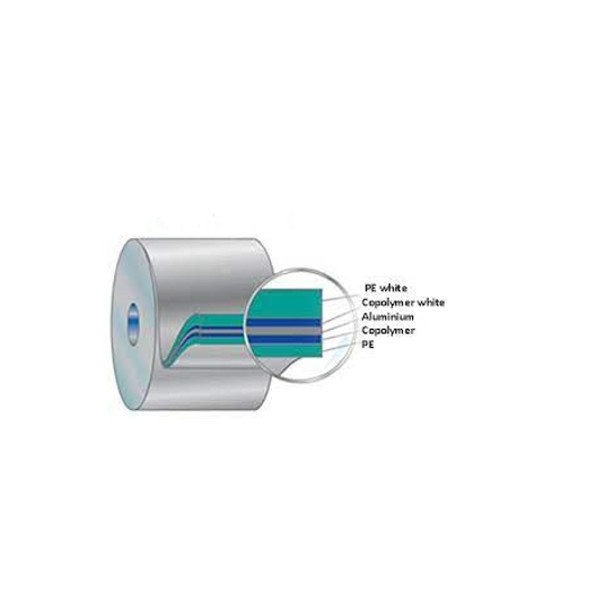

| GT-128 | EVA | 4-6 | 0.92 | High | Work as Adhesive in Multilayer film, Powder Coating and Paint. |

| GT-32 | SEBS | 1-2 | 0.91 | High | Impact modifier for PBT, PET, PC. |

| BL-760 | PLA | 8-12 | 1.25 | High | Impact modifier, Melt Strength & IV improver for PLA. |

| BA-770 | PBAT | 4-5 | 1.25 | High | Impact modifier, Melt Strength & IV improver for PBAT |

| BA-792 | PBS | 13-15 | 1.2 | High | Impact modifier, Melt Strength & IV improver for PBS |

Note: TDS & SDS available on request.

| Application | Suitable Grade(s) |

|---|---|

| PP filler (glass/talc) compound or PP FR compound with Antimony, ATH, Decca etc or PP/PA alloy. | EnGraft PP-20, PP-25 |

| Nylon 6 & Nylon 6, 6 Toughning and coupling with glass or FR Additives. | EnGraft MT-36, MT-40, MX-48, ML-56 |

| XLPE Cable Compound, LDPE filled compound, Adhesive in Multilayer Polyolefin, Aluminum Composite Panel. | EnGraft ML-56 |

| Wood PE Composites , Filled HDPE applications. | EnGraft MD-72 |

| PC/PBT/PET Impact Modification or Coupling with fillers. | EnGraft GT-450, GT-460, GX-50, GE-45 |

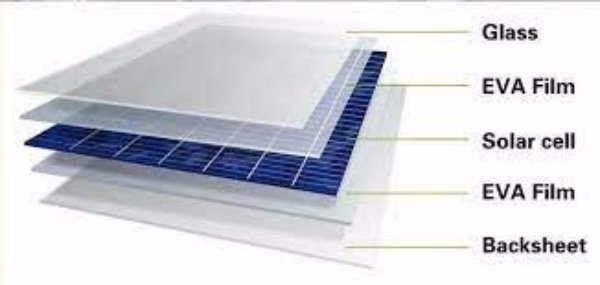

| Protective layer of solar panel, Adhesive layer of EVA film. | EnGraft ME-60 |

| Super toughning of PA and PPO. | EnGraft MS-30 |

| Toughning of PA with aging and weathering property. | EnGraft MR-92 |

| ABS filled compound, PC/ABS Aloy | EnGraft ST-10 |

Note: We can develop customized products as per customer's need. Please contact for any questions or query.

Frequently Asked Questions

Grafted Polymers are co polymers which has reactive functional group (commonly MAH or Acrylates) grafted over linear backbone of polymeric chain.

Grafted Polymers are used as Impact Modifiers, Coupling Agents, Compatibilizers and modifiers for polymers, their blends, filled and fiber-reinforced compounds based on PP, LD, HD, PC, PBT, Nylon, SAN, and Bioplastics (PLA/PBAT/PBS) etc. Polymer and metal bonding (like metal inserted plastic parts) also improves by adding few percent of grafted polymer during molding. It enhances melt strength significantly in biodegradable plastics.

Grafted Polymer’s polar functional groups attaches with other polymer’s chain or with non-polar fillers/fibers to provide interfacial adhesion hence improves compound's physical, morphological, and mechanical properties.

Generally, two different polymers are immiscible and to make perfect blend we require some compatibilizer. Grafted polymer works as compatibilizer, it helps in blending of two different polymers like PC-ABS, PC-PBT, Nylon-PP, HD-LD, PP-HD etc.

Yes, it can increase | zod Impact in PC, PBT, Nylon, PET, PP etc. by addition of 2-5% of polymer weight.

Yes, thanks to its coupling mechanism it can increase the tensile strength of glass fiber reinforced or filled PP, PBT, Nylon, and PE etc.

Yes, Grafted Polymer plays a vital role in recycling industry. It regenerates the polymer by improving its physical, morphological, and mechanical properties. Volatile content of end product cut down drastically and aesthetic/surface properties also improves. A good value addition can be put in recycled polymer by adding few percent of Grafted Polymer.

Yes, as it improves interfacial adhesion between polymer and filler, one can load high filler without compromising mechanical & rheological properties and surface finish of the compound.